Sheet metal is one of the fundamental forms used in metalworking and it can be cut and bent into a variety of shapes countless everyday objects are fabricated from sheet metal.

Sizing sheet metal operation.

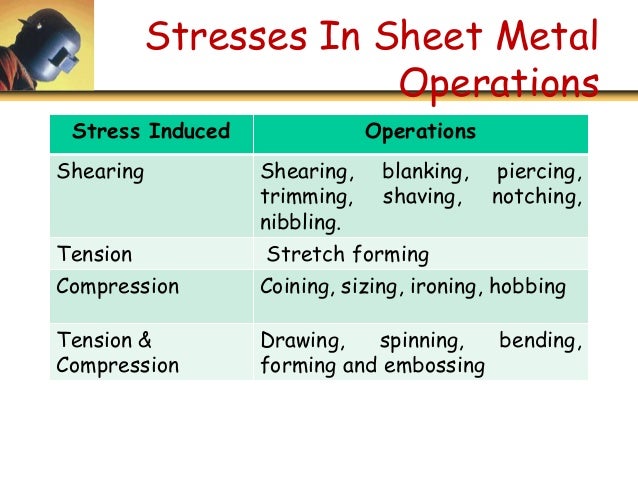

Bending causes no change in the thickness of the sheet metal.

Sheet metal is metal formed by an industrial process into thin flat pieces.

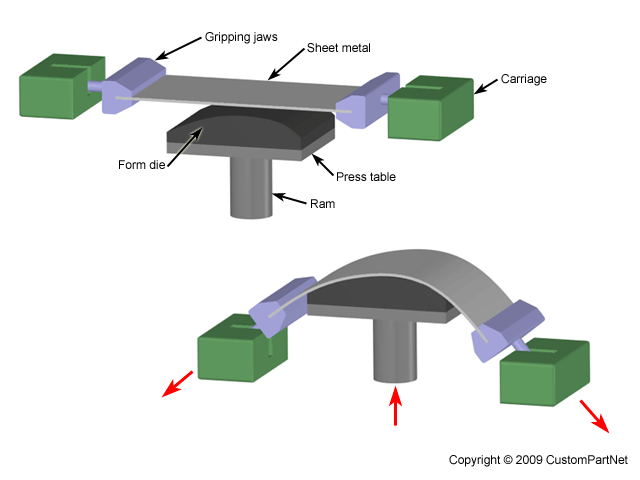

Sheet bending sheet bending is defined as the straining of the metal around a straight axis.

It is a quick and widely used way of forming ductile metals.

In coining operation the metal having good plasticity and proper size is placed within the punch and die and a tremendous pressure is applied on the blank from both ends under severe compressive loads the metal flows in the cold state and fills up the cavity of the punch and die.

Thicknesses can vary significantly.

Extremely thin sheets are considered foil or leaf and pieces thicker than 6 mm 0 25 in are considered.

Sheet metal bending methods design tips k factor 11 02 2019 bending is one of the most common sheet metal fabrication operations.

During bending operation the metal on the inner side of the neutral plane is compressed and the metal on the outer side of the neutral plane is stretched.

It is an operation by which multiples holes of smaller size are made in sheet metal called perforating operation.

The sizing is done in an open die and only the surface where the die and workpiece touch will be sized.

A beneficial feature is that in some metals the plastic flow reduces surface grain size and work hardens the surface while the material deeper in the part retains its toughness and ductility the term comes from the initial use of the.

Sizing operation is a squeezing operation that reduces the thickness of the metal.

A piece of metal whose thickness is between 0 006 0 15 mm and 0 25 inches 6 35 mm.

The diameter of the hole in sheet metal part should not be very small small holes are created by piercing operation and for manufacture small holes small sizes punches are required.

Anything thinner is referred to as a foil and thicker is considered as a plate.

It has different operations such as sizing coining riveting etc.

Also known as press braking flanging die bending folding and edging this method is used to deform a material.

Sheet thickness is generally measured in gauge.

Mainly sheet metal process can be divided into three types.

It is an operation by which metal pieces are cut from the edge of a sheet or blank is called a notching operation.

Small hole size in sheet metal requires smaller size punching tool which may leads to break during the operation.