Shop floor control has a crucial role on the shop floor as it enables the management to see what is happening in real time.

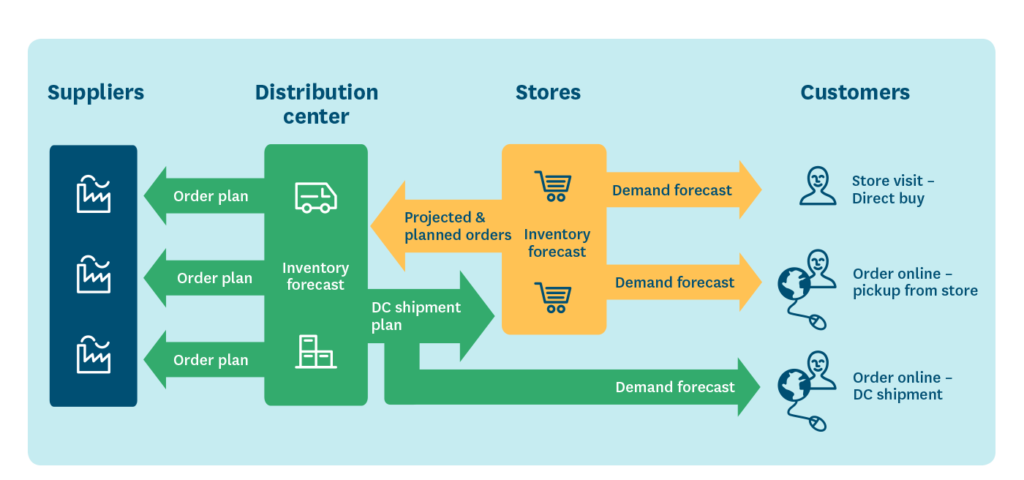

Shop floor control system distribution center.

It includes the procedures to evaluate current resource status labor machine usage and other information required to support the overall planning scheduling and costing systems related to shop floor operation.

Geneva system is a leading the warehouse management system wms encompasses all the day to day transactions that run a warehouse or distribution center with fully integrated data collection technologies such as bar code scanning bar code printing and wireless mobile data collection.

Shop floor control comprises the methods and systems to prioritize track and report against production orders and schedules.

Shop floor control systems can increase the productivity substantially and in turn the.

The distribution requirements planning master production scheduling and material requirements.

The jd edwards world shop floor control system implements the material plan by managing the flow of materials inside the plant.

This implementation divides the system into agents in charge of the management of the system while highlighting the communication channels with shop floor control equipment.

An effectively managed shop floor control system serves as a mediator between production control and the shop floor.

Shop floor control is necessary for any manufacturing assembling or processing business.

This type of tool is a major part of business process automation which industrial businesses are using to streamline workflows promote efficiency and improve revenue cycles.

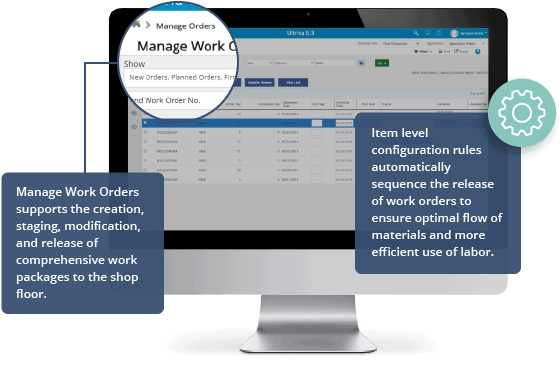

A shop floor control system should schedule manufacturing work orders in a desired priority and issue dispatch lists to control shop priorities.

Shop floor control sfc systems are systems for managing the various components of the manufacturing process.

That percentage of work in process is useful for resource planning inventory evaluations 1 and supervisor and operator.